SPhTI (Siberian Institute of Physics and Technology) TSU materials scientists have developed a new method of obtaining a biocompatible porous alloy based on titanium nickelide to create implants. Due to special terraces (roughness) on the surface of the pore walls of the alloy, the specific surface area is increased, and this reduces the time it takes for the implant to succeed. This method obtains material with improved characteristics without any specific preparation. The technology is already used to create dental implants. Now scientists are optimizing the material for its use in traumatology and oncology, and the method is being examined for a patent.

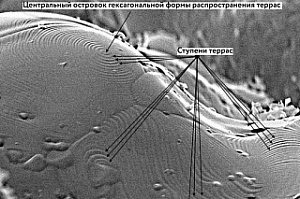

SPhTI scientists have developed specific temperature-time parameters and mechanisms for creating porous biocompatible alloys based on titanium nickelide with a developed terrace-like surface of the pore walls. At the end of 2018, patent documents were filed, and the application Method of Producing a Porous Alloy Based on Titanium Nickelide is currently in the substantial examination.

- When we use TiNi powder and defined temperature conditions, the relief is always formed without any preliminary specific preparations, complex activation procedures, thermomechanical processing, or alloying,- explains Sergey Anikeev, senior researcher at the Laboratory of Medical Alloys and Implants with Shape Memory. - At high temperatures and sintering time, a large amount of melt is formed and the porosity of the material is greatly reduced, and hence the terrace-like relief has a smaller area to form. If the temperature and sintering time is less, then the strength of the porous material is low and the terraces are almost not formed.

In the process of sintering, the scientists needed to achieve the formation of a moderate amount of melt, which wets the surface of all powder grains, while activating the processes of surface and bulk diffusion, which is necessary to create a terraced relief.

Earlier, SPhTI scientists conducted in-vitro studies and proved the positive effect of increasing the surface roughness of the pore walls. Thanks to these terraces, the implant takes root better and faster in the human body, because living cells need the ability to attach at the very first stage of implant filling. An increase in the number of adherent cells and intercellular outgrowths ensuresthe active development of cell populations in the porous structure in the future.

In May, the inventors will present their results at the international conference Shape Memory and Superelastic Technologies (Konstanz, Germany), which is the world's leading conference and exhibition on technologies and materials with shape memory effect. The studies were carried out by Sergey Anikeev and Alexander Garin, a Master’s student at the Faculty of Physics with the support of the grant of the Russian Science Foundation No. 17-79-10123 for the Presidential program of research projects Conducting Initiative Research by Young Scientists.