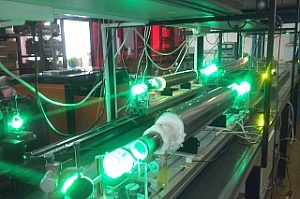

Scientists of the Faculty of Innovative Technologies commissioned by Wuhan Energy Electrical Co., Ltd. (China) produced a sealed-off strontium vapor laser. The installation is designed for cutting brittle materials and ceramics by managed thermal split.

- A focused laser beam of regulated power creates smooth cut that does not require additional processing and polishing, - says Professor Anatoly Soldatov, Dean of the Faculty of Innovative Technologies. - The use of our laser simplifies, speeds up, and reduces the cost of the details manufacturing process. The customer will be able to use the facility for cutting all types of glass and ceramics.

According to scientists of the Faculty of Innovative Technologies, the method of laser-managed thermal split of glass is attractive because the process remains less waste products and rejects, because the work is carried out to an accuracy of a few microns. In addition, the laser glass cutting can be performed by any parties from a single order to the set.

- We were able to achieve high-precision due to the modification of the laser beam, which is cut glass or ceramics, - says Anatoly Soldatov. – The installation, gathered for a Chinese company allows using a specific set of wavelengths in the visible and infrared spectrum. A few days ago, our development was sent to Wuhan (China), and in the near future our Chinese partners will be able to test all the features of the new laser.

Strontium vapor lasers are the original development of TSU scientists, they do not have analogues and have a very wide range of applications in medicine and industry, for example, for cutting and removal of hard and soft tissue during surgical procedures in dentistry, neurosurgery, orthopedics, and other areas.